The global energy crisis has promoted the rapid development of the new energy industry, and solar energy is the most important basic energy among various renewable energy sources. As a solar power generation technology that converts solar radiation energy into electrical energy, that is, the photovoltaic industry has developed rapidly in my country in recent years. According to statistics from the China Photovoltaic Industry Association, China's photovoltaic module output has ranked first in the world for 15 consecutive years, its newly installed capacity has ranked first in the world for 9 consecutive years, and its cumulative installed capacity has ranked first in the world for 7 consecutive years. It is estimated that my country's photovoltaic installed capacity will reach more than 205GW in 2022, and will reach 275GW and 300GW in the next two years.

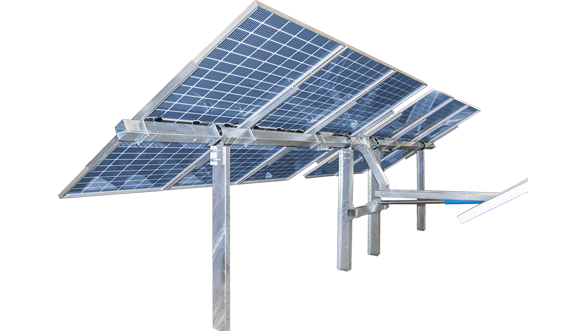

At present, the solar photovoltaic support systems commonly used in my country are divided into three types in terms of materials, mainly concrete supports, steel supports and aluminum alloy supports. Compared with concrete brackets and aluminum alloy brackets, steel brackets have stable performance, mature manufacturing technology, high bearing capacity, excellent anti-corrosion performance, beautiful appearance, and easy and fast installation. Carbon steel and supporting parts using structural anti-corrosion materials have a longer service life and a wider range of applications.

The hot-dip galvanizing process is a relatively stable and reliable steel surface treatment solution to resist environmental corrosion. Tianchuang Tube Industry integrates the atmospheric exposure environment in different areas, and uses ultra-thick hot-dip galvanizing and other technologies to ensure the service life of photovoltaic brackets. It has strong weather resistance, firm and reliable structure, and can withstand external effects such as atmospheric erosion, snow load, and wind load. , Excellent hot-dip galvanized material provides long-lasting durability and a service life of up to 30-50 years to the bracket.

Executive standard: GB/T 6723-2017 General cold-formed open section steel NB/T 10115-2018 Design rules for photovoltaic support structures

Scope of application: Provide support for solar photovoltaic panels and is an important part of photovoltaic power generation systems

Materials: Q235B-Q355B, SD402, SD550, SD350

Product advantages

The company is located in Handan, the capital of steel at the junction of the four provinces of Shanxi, Hebei, Shandong and Henan. It has established long-term and stable strategic cooperative relations with many well-known domestic steel companies, and has unique advantages in raw material procurement. We have established a quality management process centered on customer needs, with checks at all levels and strict control of the process, so that the delivery time of goods is more guaranteed. We have introduced foreign advanced technology and established the first fully automated hot-dip galvanizing production line in the country. We focus on hot-dip galvanizing for photovoltaic brackets and accessories, carefully select high-quality zinc ingot raw materials, and coat the metal surface with uniform controllability and strong adhesion Antioxidant suit. Compared with traditional electro-galvanizing, mechanical galvanizing, and powder galvanizing, it is more durable, and the tensile force and shear force are not affected, and all indicators meet the national requirements.

C-shaped steel | |||

Specification | Thickness | Material | Anticorrosion |

C60 | 2.0-2.5 | Q235B-Q355B | Hot dip galvanized |

C70 | 2.0-2.5 | Q235B-Q356B | Hot dip galvanized |

C80 | 2.0-2.5 | Q235B-Q357B | Hot dip galvanized |

C90 | 2.0-2.5 | Q235B-Q358B | Hot dip galvanized |

C110 | 2.0-2.5 | Q235B-Q359B | Hot dip galvanized |

C120 | 2.0-2.5 | Q235B-Q360B | Hot dip galvanized |

C140 | 2.0-2.5 | Q235B-Q361B | Hot dip galvanized |

C160 | 2.0-2.5 | Q235B-Q362B | Hot dip galvanized |

C60 | 1.6-2.5 | SD402、SD550、SD350 | Zinc Aluminum Magnesium |

C70 | 1.6-2.5 | SD402、SD550、SD351 | Zinc Aluminum Magnesium |

C80 | 1.6-2.5 | SD402、SD550、SD352 | Zinc Aluminum Magnesium |

C90 | 1.6-2.5 | SD402、SD550、SD353 | Zinc Aluminum Magnesium |

C110 | 1.6-2.5 | SD402、SD550、SD354 | Zinc Aluminum Magnesium |

C120 | 1.6-2.5 | SD402、SD550、SD355 | Zinc Aluminum Magnesium |

C140 | 1.6-2.5 | SD402、SD550、SD356 | Zinc Aluminum Magnesium |

C160 | 1.6-2.5 | SD402、SD550、SD357 | Zinc Aluminum Magnesium |

1. Steel bracket material:

The bracket shall be made of carbon steel profile or cold-formed thin-walled steel. The material and performance requirements are as follows:

(1) The main material of the steel structure is Q235B, S250GD, Q355B, S350GD and other materials

(2) The tensile strength, elongation, yield point, cold bending test and other mechanical performance requirements of the main material of the steel structure must comply with the relevant regulations of "Carbon Structural Steel" (GB/T700-2007), according to the national steel Standard execution.

(3) The content of chemical elements such as carbon, sulfur and phosphorus in the main material of the steel structure must comply with the relevant regulations of "Carbon Structural Steel" (GB/T700-2007).

(4) The size, shape, weight and allowable deviation of the steel must comply with the "Size, Shape, Weight and Allowable Deviation of Cold-Formed Hollow Section Steel for Structural Use" (GB/T6728-2002) and "General Cold-Formed Open Section Steel Dimensions" , shape, weight and allowable deviation" (GB/T 6723-2008) the relevant regulations, strictly prohibit the use of section steel that does not meet the relevant requirements. The bending degree of 1-shaped steel should not exceed 2 mm per meter, and the total bending degree should not exceed 0.2% of the total length.

2. Section steel, steel components and fasteners

It should meet the requirements in GB/T13912-2002 of "Technical Requirements and Test Methods for Hot-dip Galvanized Coatings of Iron and Steel Parts with Metal Covering", and the manufacturer is required to provide a test report or an anti-corrosion evaluation report. Galvanized thickness detection: The thickness of the galvanized layer shall be tested according to the method provided in "Technical Requirements and Experimental Methods for Hot-Dip Galvanized Coating of Metal Covering Steel Parts".

3. Mechanical performance requirements

The deformation of photovoltaic support and components meets the requirements of "Code for Design of Photovoltaic Power Stations" GB50797-2012 and other national regulations. The cross-section and wall thickness selection of the bracket profile need to be calculated. The design of the fixed support structure is in accordance with the current national building structure load codes, steel structure design standards and other specifications to ensure that the structure meets the requirements of strength, stability and stiffness during transportation, installation and use, and meets the requirements of earthquake resistance, wind resistance and corrosion resistance.

4. Anti-corrosion requirements

(1) Steel components adopt the anti-corrosion method of metal protective layer. If the steel structural support adopts hot-dip galvanized coating, the hot-dip galvanized coating must meet the relevant requirements of "Technical Requirements and Experimental Methods for Hot-dip Galvanized Coatings of Steel Parts with Metal Coverings" (GB/T13912-2002). The thickness of the zinc layer meets the national standard and customer requirements. If magnesium-aluminum-zinc plating is used, the average thickness of the magnesium-aluminum-zinc anti-corrosion coating meets the national standard and customer requirements.

(2) Detection of galvanized thickness: The thickness of galvanized layer shall be tested according to the method provided in "Technical Requirements and Experimental Methods for Hot-dip Galvanized Coating of Steel Parts with Metal Covering".

1. Storage: Profiles should be stored in a dry and ventilated warehouse, pay attention to prevent corrosion and pollution. Profiles should be sorted and stacked, and the types, specifications and batch numbers should be marked on the tags, and they should be placed safely to prevent deformation and damage.

2. Loading: When lifting, prevent component damage or deformation. When loading, it should be placed stably, in a moderate position, and reinforced reliably. Danger warning signs should be hung when transporting super-long, super-wide, and super-high parts. Pay attention to protecting roads, bridges, Security of communications, power and other facilities

3. Transportation: Steel structural components should be properly bound during transportation and hoisting to prevent deformation, damage and damage to the galvanized layer.

Call us on:

Call us on:  Email Us:

Email Us:  Yongyang Street, East Jianshe Road, Yongnian Industrial Park, Handan City, Hebei Province, China

Yongyang Street, East Jianshe Road, Yongnian Industrial Park, Handan City, Hebei Province, China